Result

Elevate your team’s expertise with the Engineering Pro Subscription—unlimited access to our full engineering curriculum, updated continuously. It includes everything in the Essentials bundle, plus in-depth, process-focused training that keeps skills sharp and production lines running smoothly.

Give your engineers the curriculum they deserve. Subscribe now to Engineering Pro and turn onboarding into ongoing excellence.

Help your team enhance product reliability, reduce rework and scrap, and ensure customer satisfaction. This comprehensive overview of process control methodology will empower technicians and engineers to utilize the IPC-A-610 Standard and its associated Handbook to consistently meet acceptance criteria throughout the assembly process.

This course introduces participants to the causes of ESD and the steps you can take to mitigate its effects when handling, storing or transporting ESD-sensitive components in a manufacturing facility. These preventive measures and their application are based on ANSI/ESD S20.20 and other relevant standards.

This course introduces participants to the causes of Foreign Object Debris (FOD) and the steps you can take to mitigate its effects when handling, storing, or transporting items in a manufacturing facility. After completing this course, you will be able to employ the key tools, materials, and processes designed to prevent and control the effects of FOD within a manufacturing facility.

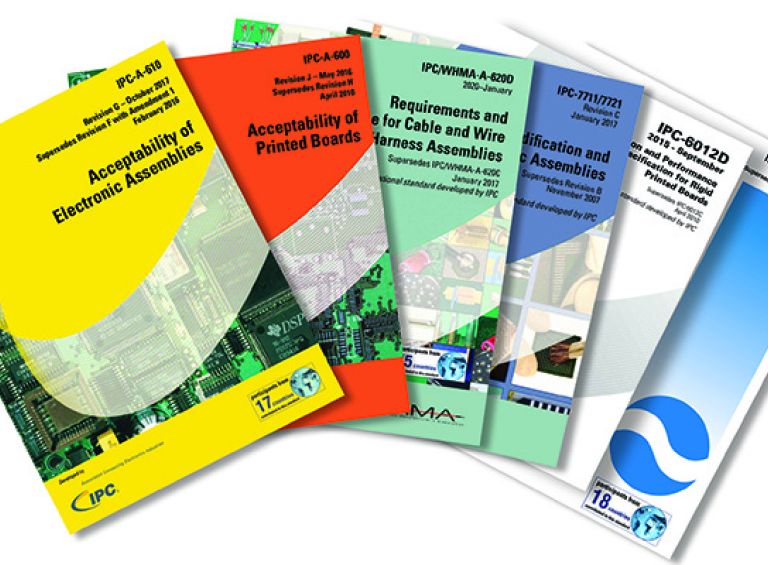

Identify the most common IPC standards used by electronics manufacturers, explain product classes and acceptability conditions as outlined in IPC standards, utilize IPC standards to precisely locate specific acceptance criteria, and use figures, illustrations, tables, and units of measurement to assess compliance.

Onboarding manufacturing engineers new to the electronics industry can be a daunting task. What if you had a self-paced course that provides a comprehensive overview of the roles and responsibilities of manufacturing engineers in our industry? IPC worked with industry subject-matter experts and instructional designers to create an introductory course that takes approximately 3-1/2 hours to complete. In addition to understanding the role, participants will also learn to use documentation control systems, product identification, and product traceability.

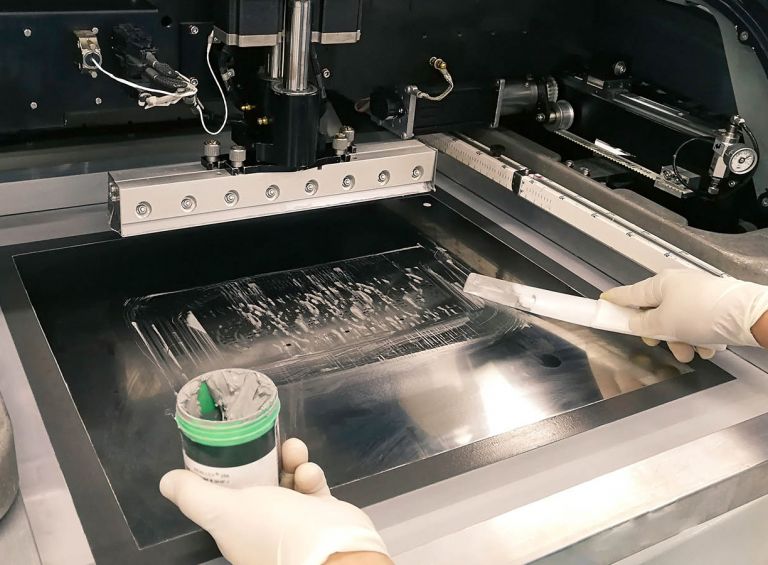

A comprehensive overview of the stencil printing process for a manufacturing engineer. Participants will learn how to select and store solder pastes & adhesives. They will also learn how to create and maintain stencils, the function of the stencil printer, as well as how to set up the stencil printer for a new product introduction, or NPI, run.

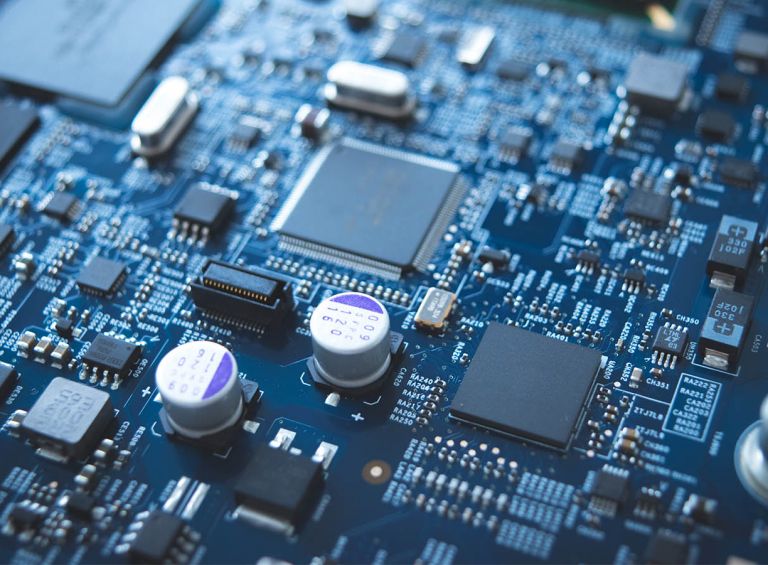

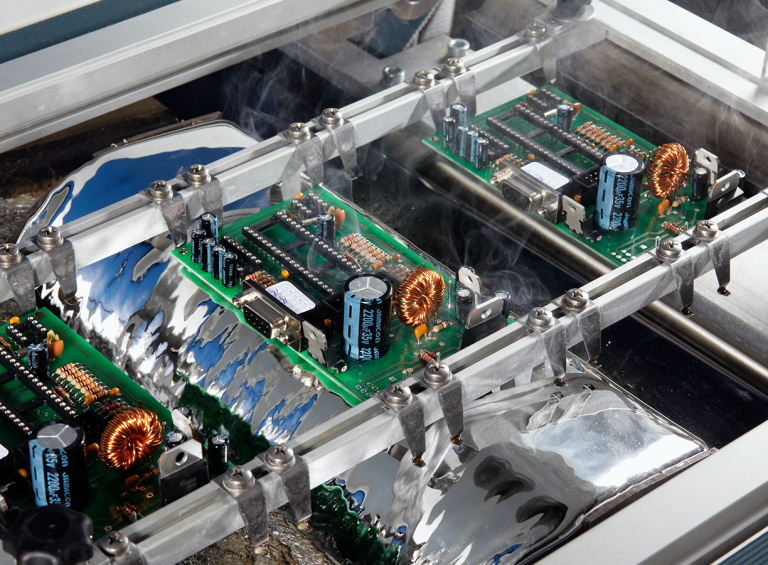

This course provides a comprehensive overview of the surface mount assembly process including information on component considerations, selecting and setting up pick and place machines, and the reflow process. Participants can take this content-specific course to learn more about the role of manufacturing engineers regardless of company size and industry sector.

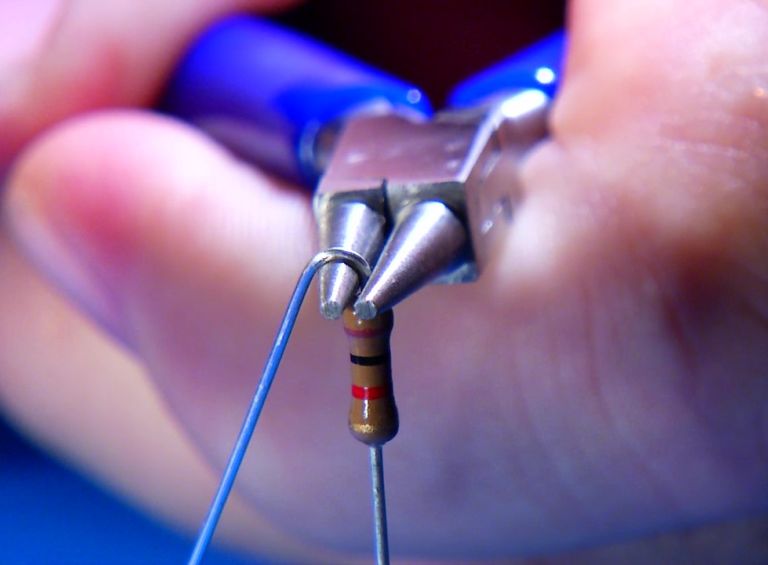

This course provides a comprehensive overview of component preparation, tool selection, manual component insertion, and automated component insertion in electronics assembly with through-hole components. Participants can take this content-specific course to learn more about the role of manufacturing engineers regardless of company size and industry sector.

In this course, you will be able to set up, monitor, and maintain wave and selective soldering equipment to support consistent, high-quality production. You will know how to apply process parameters, interpret profile data, select the right nozzles and solder pot configuration, and implement maintenance procedures that reduce variation, prevent common defects, and keep your line running efficiently.

In the competitive printed circuit board fabrication industry, high reliability and high yields are crucial for profitability. That's why process and manufacturing engineers involved in fabrication, assembly, and procurement need to have the necessary knowledge and skills to produce and evaluate top-quality printed circuit boards. This includes understanding materials, chemical processes, equipment parameters, and their impact on board quality.

After completing this course, you will be able to:

Identify and correct control processes that negatively affect circuit board quality

Establish the root cause of potential defects to minimize and prevent loss of quality

Recognize the interrelationships of PCB materials, processes, and equipment and how these relationships affect PCB and PCA quality

Identify the root cause and corrective action for PCB defects, such as interconnect separation, delamination, wedge voids, plating folds, microvoids, surface pitting, and hole wall pull-away

Identify the root cause and corrective action for electrodeposition defects, such as mouse bites, pitting, and domed or crown plating

Identify the root cause and corrective action for solderability and assembly-related issues, such as outgassing, black pad, creep corrosion, and blow holes

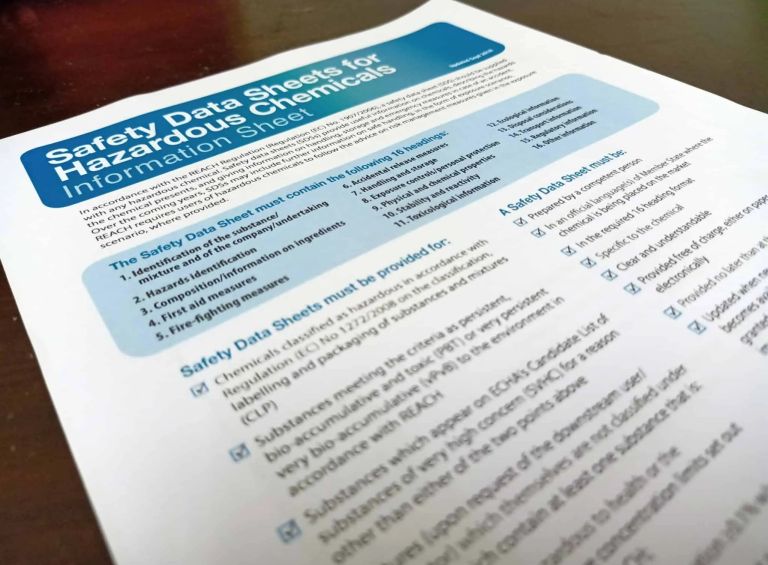

In electronics manufacturing, chemicals are everywhere, from cleaning agents to conformal coatings, and mishandling them can risk health, safety, and production. This course equips engineers with the skills to read, interpret, and apply Safety Data Sheets (SDS) to make informed decisions that keep people safe and processes compliant.