Result

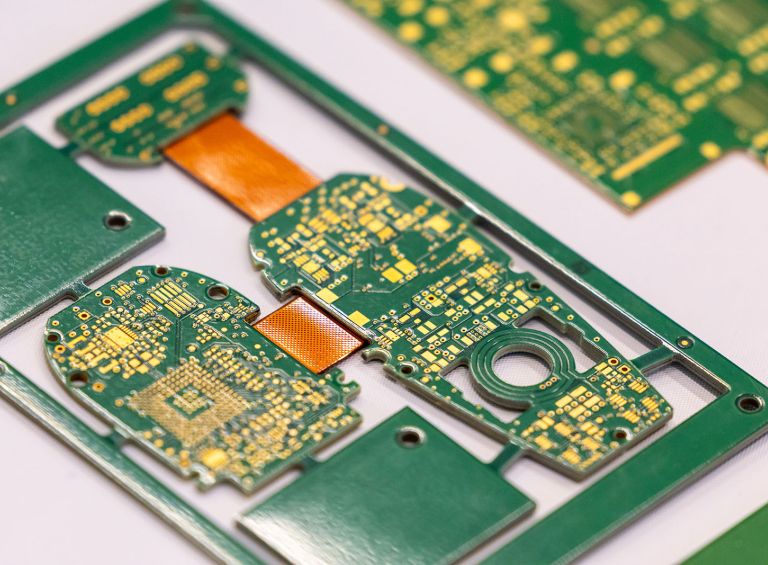

This course focuses on BTC packaging and downstream manufacturing assembly, covering various BTC configurations such as QFN, LGA, MLF, SON, and DFN in both periphery-leaded and solder-ball array packages. By the end of this course, you’ll have the knowledge and practical insights needed to achieve high-yield production and build reliable BTC assemblies in today’s demanding electronics industry.

This course introduces participants to the causes of ESD and the steps you can take to mitigate its effects when handling, storing or transporting ESD-sensitive components in a manufacturing facility. These preventive measures and their application are based on ANSI/ESD S20.20 and other relevant standards.

This course introduces participants to the causes of Foreign Object Debris (FOD) and the steps you can take to mitigate its effects when handling, storing, or transporting items in a manufacturing facility. After completing this course, you will be able to employ the key tools, materials, and processes designed to prevent and control the effects of FOD within a manufacturing facility.

Taught by a certified industry expert with more than 25 years of experience in the field, this 6-week online program introduces participants to the concepts and skills required to create real-world designs that comply with IPC standards. This introductory course will focus on front-end design concepts such as schematic capture, library parts creation, basic electrical engineering concepts, and documentation.

In un settore altamente competitivo come quello dell'elettronica, le conoscenze e le competenze di chi progetta il layout del circuito stampato (PCB) e del suo assemblaggio (PBA) hanno un impatto diretto sul successo o sul fallimento del prodotto e incide sul time-to-market. Il corso online sui Fondamenti di PCB IPC è progettato per fornire le competenze necessarie per creare schemi che rispecchino accuratamente l’intento progettuale e la conformità agli standard IPC per la documentazione dello schema.

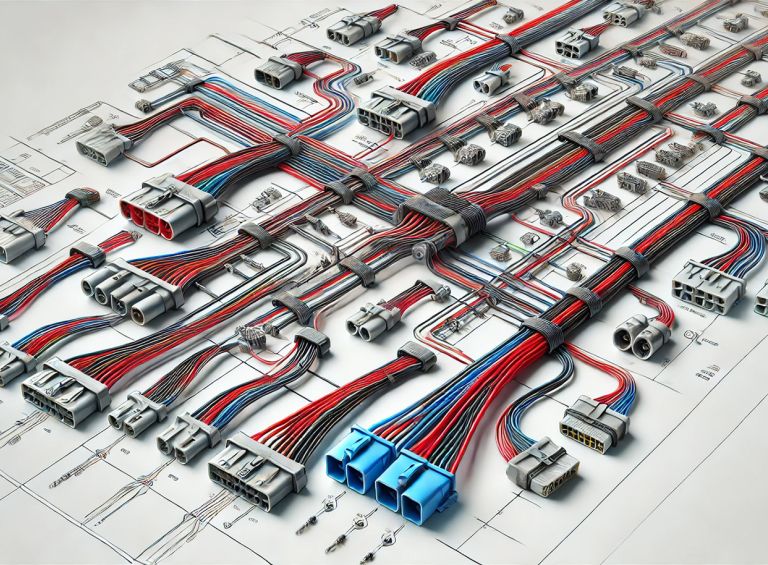

This course is designed to provide designers, assemblers, engineers, and management with a wide overview of PCBA and wire harness manufacturing processes and relevant standards used by industry. Upon completion, participants will be able to:

• Understand the structure and purpose of IPC standards in electronics manufacturing.

• Navigate the IPC standards library and specification tree.

• Identify IPC standards applicable to design, fabrication, assembly, and testing of PCBA and Wire Harnesses.

• Explore the standards covering processes and materials for PCB assembly and testing.

• Create awareness for special industry segments such as automotive and military standards.

Miniaturizing electronics while increasing circuit density and functionality requires advanced

packaging solutions. Among them, Package-on-Package (PoP) is widely used in Integrated Circuit (IC)

design. This course explores PoP packaging and its role in downstream manufacturing assembly,

focusing on high-yield production and product reliability.

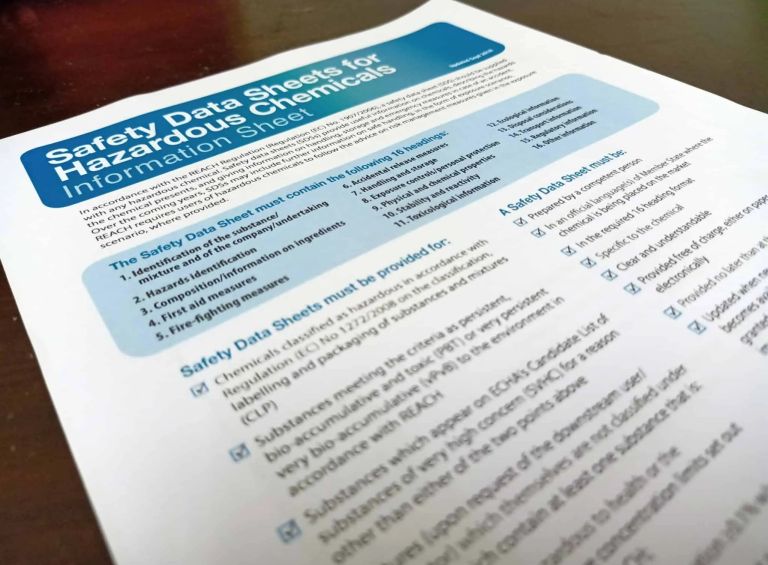

In electronics manufacturing, chemicals are everywhere, from cleaning agents to conformal coatings, and mishandling them can risk health, safety, and production. This course equips engineers with the skills to read, interpret, and apply Safety Data Sheets (SDS) to make informed decisions that keep people safe and processes compliant.